The Benefits of Cleaning Without Consumables

With the advance of laser technology in surface cleaning, manufacturers are becoming aware of the extent to which laser cleaning can help them. From the automotive and aerospace industries to more general industrial applications, many uses of this revolutionary cleaning technique are still unknown.

Best performed using a pulsed laser, laser cleaning can replace traditional cleaning methods to remove rust, oxide, paint and other contaminants from metal surfaces. Emerging applications include weld cleaning, mold cleaning, tool cleaning and surface preparation.

Summary of Laser Cleaning System

Everybody is looking for cleaner and non-invasive cleaning methods

There are a variety of cleaning methods in traditional cleaning industry, such as chemical and mechanical methods. Now the environmental protection and safety awareness are increasing drastically, environmental protection laws and regulations become more and more stringent, so available chemicals methods in this field become less. Everybody is looking for cleaner and non-invasive cleaning methods. Nevertheless the laser cleaning is characterized by non-abrasive, non-contact, non-thermal effects and suitable for various material surface cleaning, which is considered to be the most reliable, effective and safety solution.

Laser cleaning equipment is a high-tech and latest product of surface cleaning. It is easy to install, operate and automated. Only turn on the power and then you can start to clean without chemical reagent, medium and water. it is with advantages of manual adjustment of focus, spherical surface cleaning and high cleanliness of cleaning surface. It can remove the resin, oil contamination, stains, dirt, rust, coating, carbon rests, burned rubbe or plastics, plating and paint on the surface of different shape metal objects and it removes perfectly in the stone caving surface.

Get Rid of Consumables & Go Green

As a green technology, laser cleaning replaces methods that remove rust with consumables or chemicals.

It’s the only solution that meets environmental protection regulations.

Plus, pulsed fiber lasers have low power consumption.

Laser cleaning does generate a small amount of dust in the air.

It can be vacuumed instantly with a dust extraction system, which we provide and preconfigure for you if needed.

COVER LAYERS REMOVAL AND DECOATING

Paint - Rust - Graffiti - Grease - Carbonized Material

SURFACE CLEANING and RESTAURATION

Dirt & Contamination Removal

PRE-TREATEMENT OF SURFACE

Before Bonding, coating, painting, Brazing, Welding

How does laser cleaning work?

Laser Cleaning Technology - WORKING PRINCIPLE

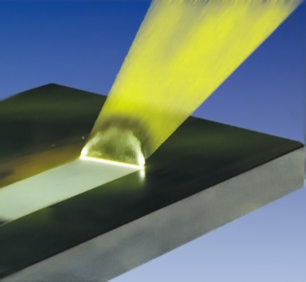

Laser cleaning technology works by sending nanosecond-length pulses of laser light towards a surface. When it interacts with contaminants like rust, coating, paint,.. that absorb the pulses of laser light, the contaminants or coating particles will either turn into a gas or the pressure of the interaction will cause particles to free from the surface.

Laser cleaning - or ablation - is the process of clearing away undesired material from a solid surface by irradiating it with a laser beam. By absorbing the energy of the laser beam, the targeted material is heated very quickly, making it evaporate or sublimate. As the surface below does not absorb any energy, it stays untouched.

By manipulating the laser flux, its wavelength and its pulse length, the amount of material that is being removed by a single laser pulse can be controlled with extreme precision. Making laser cleaning equally suitable for rapid and deep rust removal as for removing only one thin layer of paint, without damaging the base coat.

Laser Cleaning parameters explained

Laser cleaning or surface cleaning by Flash laser heating using short‐pulsed laser irradiation of a surface is demonstrated to be a promising new approach for effective removal of particulate contaminations of sizes as small as 0.1 μm.

This is very useful because micron‐ and submicron‐sized particulates adhere tenaciously onto a solid surface, and conventional cleaning techniques are inadequate for removal.

We find that laser cleaning with highest efficiency is achieved by choosing a laser wavelength ( infra red-A or UV) that is strongly absorbed by the surface together with pulse depositing a water film of thickness on the order of microns on the surface momentarily before the pulsed laser irradiation. This permits the effective removal of particles smaller than ∼20 μm, down to as small as 0.1 μm, from a solid surface using a modest laser power starting at ∼0.1 J/cm2.

Beam intensity

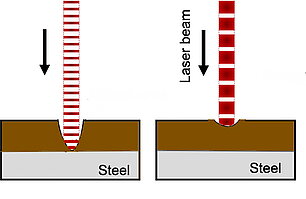

Beam intensity is the crucial parameter in laser cleaning process. If it is not correctly selected, it may damage the substrate. The beam intensity and their effects on the substrate and the product to remove influence a lot the speed of removing and the way of removing.

Wavelength of laser

Beam Area

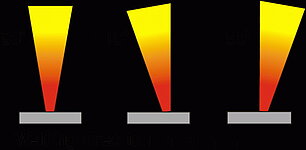

Beam size is one of the factors that influence cleaning efficiency and time of cleaning.

A smaller beam size is normally good for laser cleaning process, because of the high removal rate and the less cleaning time. However, if the laser beam area is too small, it may damage the surface. Thus the beam size should be selected carefully

Pulse duration

Pulse duration is the time it takes for the laser to emit one pulse

In the case of long-pulse lasers and continuous lasers (CW), the removal of surface material like pâint, dirt, oil, etc.. is done by vaporization.

At the same time, ablation of the material occurs in the case of high power short-pulse lasers, by acoustic shock waves created by the absorption of highintensity laser energy. A higher removal rate can be achieved in the case of short pulses for a fixed amount of laser energy.

If the pulse duration is too short, the cleaning is not efficient, at the same time if pulse duration is too long, substrate is affected by heat. Thus appropriate pulse duration should be selected. Therefor are needed laser sources with fine pulse adjusting.

Pulse repetition rate

Pulse repetition is the number of pulses per second.

If dwell time is too short, the dust from the graffiti, dirt, oil,.. and the laser pulse interfere with each other. Hence the laser pulses do not reach the target. If the pulse repetition rate is too long, the cleaning takes more time. Therefore pulse repetition rate should be selected as appropriate.

Number of pulses

Scanning speed

Angle of incidence of the laser beam

Is laser cleaning good for me?

What is laser cleaning and how does it work?

Laser cleaning system distributes thousands of focused laser pulses per second onto the target surface. These powerful beam pulses are linearly deflected & placed adjacent to each other. Most laser energy is absorbed by the target surface, creating micro-bursts of plasma that decompose the target layer/coating/contaminant through sublimation. Thermal energy is rapidly dispersed as laser vaporized residues are removed from the substrate. Process speed relates to the laser energy absorption properties of the target material & laser power as measured in watts.

Does laser cleaning damage the underling surface?

The substrate material, unlike the target contaminant or coating, normally does not absorb, but rather reflects laser beam energy. Once a reflective substrate material has been reached, the laser ablation process automatically stops. Due to typically high reflection factors, metallic surfaces are especially suitable for laser cleaning. Precise laser beam adjustments enable treatment for many applications without undesirable mechanical or thermal effects to the substrate.

Where does the stuff removed by the laser cleaning go?

An integrated suction system provides continuous vacuum at the laser target interface. This immediately captures ablated contaminants, vaporized coating fumes & particles, which are pulled through a hose to a modular fume extractor with high efficiency particle & carbon filters. Laser cleaning … a dust-free process with nothing to clean-up!

The Laser Cleaning Advantage

| Laser Cleaning | Chemical Products | Sand Blasting | Hand Cleaning | Laser Cleaning |

|---|---|---|---|---|

| Precise/selective cleaning | ✓ | X | ✓ | ✓ |

| No consumables needed | X | X | X | ✓ |

| No collateral waste | X | X | ✓ | ✓ |

| No infiltration | X | X | ✓ | ✓ |

| Can clean sensitive parts | ✓ | X | X | ✓ |

| Low noise operation | ✓ | X | ✓ | ✓ |

| Possibility to clean in motion | X | X | ✓ | ✓ |

| No rinsing/drying | X | ✓ | ✓ | ✓ |

| Possibility to clean hot tools/parts | X | X | X | ✓ |

| No need to dismantle tools/moulds | X | X | ✓ | ✓ |

| Minimal work area required | X | X | ✓ | ✓ |

| Low power consumption | ✓ | X | ✓ | ✓ |

Laserreiniging in belgië- laserreinigen in Nederland - laser cleaning in the UK - laser cleaning in Ireland - laser cleaning in South Africa - laser skoonmaak in Suid-Afrika - nettoyage laser en France - nettoyage laser en Belgique - nettoyage laser au Luxembourg - Laserreinigung in Deutschland - Laserreinigung in Österreich - limpieza láser en españa - pulizia laser in italia - limpeza a laser em portugal - Laser cleaning in scotland - laserrensning i danmark - curățarea cu laser în Romania - nettoyage laser en Suisse - Laserreinigung in der Schweiz - laser bidezko garbiketa espainian - limpieza laser en españa - laserové čištění v česku - Laserové zváranie na slovensku - lasersko čiščenje v sloveniji - lasersko čišćenje u hrvatskoj - lasersko čišćenje u bosni - ласерско чишћење у србији - лазерно почистване в българия - καθαρισμός με λέιζερ στην Ελλάδα - czyszczenie laserowe w polsce - лазерне чищення в україні - лазерная чистка в украине - laserpuhastus valges venemaal - Лазерная зварка ў Беларусі - лазерная чыстка ў белай расіі - laserpuhdistus Suomessa - laserrengöring i sverige - laserrengjøring i norge - Laser cleaning in united states - Laser cleaning in canada - nettoyage au laser au Canada - türkiye'de lazer temizleme - ניקוי לייזר בישראל