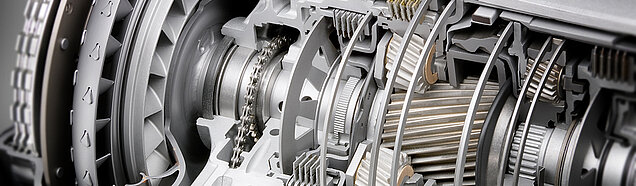

100 Watt laser cleaning of a recycled Hydraulic pump group

Automotive Parts Laser Cleaning Recuperation and Restauration

Lasermach provides a cleaning solution designed to provide the highest quality and efficiency to Automotive parts Restoration. We offer several solutions to make processes move along more efficiently and cost-effectively. The latest technology can offer the best possible cleaning treatment.

Further, laser cleaning has been proven as the perfect option to not only prepare surfaces for bonding but to generate a corrosion-resistant coating for bonding. Many clients are choosing solutions from Lasermach as the technology to use for corrosion resistance and bond prep all in one package.

Car parts recycling by laser cleaning

Laser cleaning systems are highly efficient at removing impurities on a material, but the process is not restorative and cannot repair defects that are close to the substrate surface. However, the removal of bulk surface material allows for the inspection of the components after cleaning.

This is particularly important for component-reecuperation industries, where small defects can have dramatic implications. As there is no need for a secondary process to remove cleaning media, the inspection can occur either during the cleaning process or immediately after the cleaning process.

The process to remove impurities is a challenging task, and lasers have minimal impact on substrates and leave no residue behind. For the cleaning process, both handled and standalone lasers are used for a wide range of automotive recuperation parts.