MOULD CLEANING BY LASER

As they leave no blast media residue or disposal, both our Low and High Power laser equipment are the optimal solution for cleaning moulds used for rubber, plastic, glass and composite products.

FOOD MOULDS

For the food industry hygiene is very important. Food has to be processed in a very clean environment following very strict regulations. To meet these regulations, it is necessary to clean the moulds in an environmentally friendly way. Sand-blasting or the use of chemical solvents is a no-go. Laser cleaning is an excellent solution because it is clean and very easy to integrate in-line.

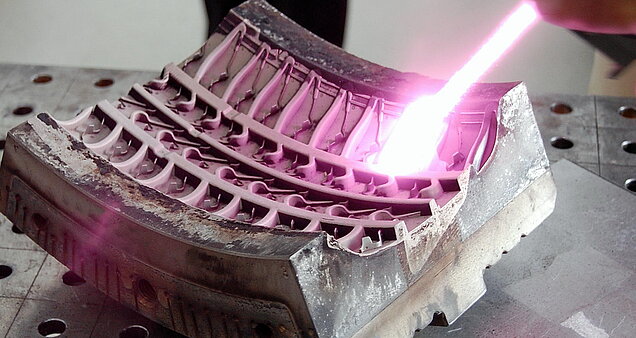

RUBBER MOULDS

Speed is the decisive factor when it comes to rubber mould cleaning. For example, cleaning a tire mould (for a passenger car) takes eight hours of machine down-time and the same amount of manual labour time if done in the traditional way (blasting or chemical cleaning). Laser cleaning systems can clean till 2m² per hour, a drastical improvement. A lot of aluminium moulds are used in the rubber industry. Laser cleaning makes sure the base material is not affected by the technology, surpassing sand-blasting. On top of that, laser cleaning technology is able to clean thicker and sturdier contamination, which is very difficult using the traditional methods.

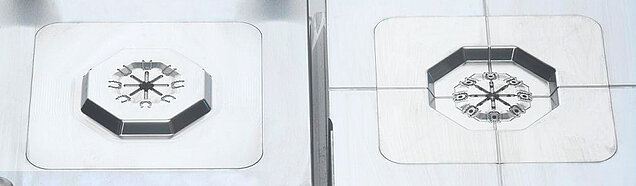

PLASTIC MOULDS

Just like with rubber moulds, speed is a crucial factor when it comes to cleaning. Laser cleaning succeeds in reaching this speed without damaging the base material. A lot of plastic moulds have a specific structure that may not be damaged when cleaning. Traditional cleaning methods like sand-blasting cannot guarantee this preservation, laser cleaning can. On top of that, a lot of moulds are designed with a high gloss finish to transfer to the final product. Laser cleaning makes sure this high gloss is not affected by the cleaning.

GLASS MOULDS

Glass moulds have very specific needs when it comes to cleaning. Some of the most important difficulties when it comes to glass cleaning are:

- There shouldn't be any increase in volume (1 liter bottle is and must stay 1 liter bottle) . Because of this strict volume policy the base material of the mould cannot be affected.

- Closing edges have to be preserved to make sure no burrs are introduced.

- A lot of small holes can be found in glass moulds to make sure air can get out. Laser cleaning ensures good cleaning of these holes and of course no residues are left behind.

COMPOSITES MOULDS

In Aeronautics and automotive, laser cleaning is used to clean the wing moulds of airplanes and the form moulds of high-tech carbon fiber car parts. The structure of the moulds has to be preserved, so sand-blasting is not a good option if you want to clean these giants. Using chemicals can be very dangerous because the base material might be harmed by the toxic chemicals. Apart from that, the chemical waste would be outrageous. Because of the large surfaces that have to be cleaned, high speeds are demanded.

Thanks to efficiency, perfectly clean surface and low running costs, the laser cleaning technology is quickly becoming a standard in the European plastic and rubber injection industry. Everything suggests that laser cleaning will become a standard in the world as well.

Technologies of mold cleaning, which are substituted by laser:

Dry ice blasting

Chemical cleaning

Mechanical cleaning

Manual cleaning

Key advantages of laser surface cleaning in the mould industry

- Laser can clean surfaces that cannot be cleaned by conventional methods

- Molds can be cleaned on-site without dismantling

- Highly-effective and green technology with savings up to 90 % of operational costs

- Fast return of investment – it is proven that the investment is paid back by savings on operational costs of cleaning

- Low failure rate and long lifetime

- Laser cleaning is contactless and gentle to the base material

- Perfect surface cleaning in one crossover instead of long repeated cycles, which are required when using conventional methods

Areas of use and application

- Cleaning of plastic and rubber molds without surface treatment

- Polished and sand-blasted surfaces

- Surfaces with mirrored gloss

- Work ejectors and mold peripheries

- Inner and outer parts

- Selective rust removal

- Cleaning of oil films and separators

- Removing the residues of steamed coatings after the plating and painting process

- Stripping organic impurities from plastic and composite parts